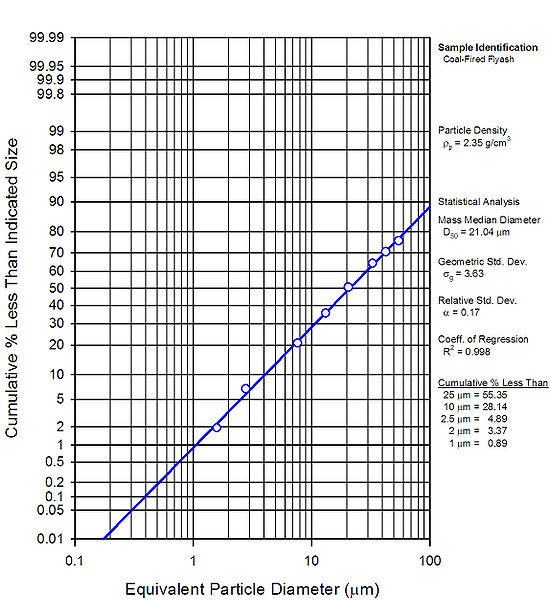

Particle-size Distribution

The particle-size distribution (PSD) of a powder, or granular material, or particles dispersed in fluid, is a list of values or a mathematical function that defines the relative amount, typically by mass, of particles present according to size. PSD is also known as grain size distribution.

Significance

The PSD of a material can be important in understanding its physical and chemical properties. It affects the strength and load-bearing properties of rocks and soils. It affects the reactivity of solids participating in chemical reactions, and needs to be tightly controlled in many industrial products such as the manufacture of printer toner and cosmetics.

|

Significance in the collection of particulate matter

Particle size distribution can greatly affect the efficacy of any collection device.

Settling chambers will normally only collect very large particles, those that can be separated using sieve trays.

Centrifugal collectors will normally collect particles down to about 20 μm. Higher efficiency models can collect particles down to 10 μm.

Fabric filters are one of the most efficient and cost effective types of dust collectors available and can achieve a collection efficiency of more than 99% for very fine particules.

Wet scrubbers that use liquid are commonly known as wet scrubbers. In these systems, the scrubbing liquid (usually water) comes into contact with a gas stream containing dust particles. The greater the contact of the gas and liquid streams, the higher the dust removal efficiency.

Electrostatic precipitators use electrostatic forces to separate dust particles from exhaust gases. They can be very efficient at the collection of very fine particles.

Filter Press used for filtering liquids by cake filtration mechanism. The PSD plays an important part in the cake formation , cake resistance, and cake characteristics. The filterability of the liquid is determined largely by the size of the particles.

Sampling

Before a PSD can be determined, it is vital that a representative sample is obtained. In the case where the material to be analysed is flowing, the sample must be withdrawn from the stream in such a way that the sample has the same proportions of particle sizes as the stream. The best way to do this is to take many samples of the whole stream over a period, instead of taking a portion of the stream for the whole time.p.6 In the case where the material is in a heap, scoop or thief sampling needs to be done, which is inaccurate: the sample should ideally have been taken while the powder was flowing towards the heap.p.10 After sampling, the sample volume typically needs to be reduced. The material to be analysed must be carefully blended, and the sample withdrawn using techniques that avoid size segregation, for example using a rotary divider p.5. Particular attention must be paid to avoidance of loss of fines during manipulation of the sample.

Mathematical models

1.Probability distributions

The log-normal distribution is often used to approximate the particle size distribution of aerosols, aquatic particles and pulverized material.

The Weibull distribution or Rosin Rammler distribution is a useful distribution for representing particle size distributions generated by grinding, milling and crushing operations.

The log-hyperbolic distribution was proposed by Bagnold and Barndorff-Nielsen to model the particle-size distribution of naturally occurring sediments.

This model suffers from having non-unique solutions for a range of probability coefficients.

The skew log-Laplace model was proposed by Fieller, Gilbertson and Olbricht as a simpler alternative to the log-hyperbolic distribution.

2.Rosin-Rammler distribution

The Weibull distribution, now named for Waloddi Weibull was first identified by Fréchet (1927) and first applied by Rosin & Rammler (1933) to describe particle size distributions. It is still widely used in mineral processing to describe particle size distributions in comminution processes.

Information from wikipedia.

If you have any interest in our products, please feel free to contact us by email: sales@chinatungsten.com or by telephone:+86 592 5129696.

More info>>