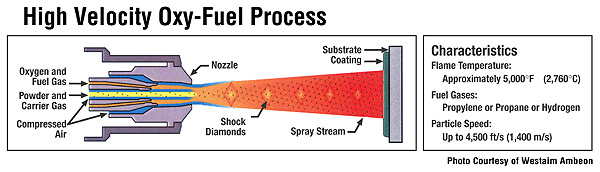

Tungsten Powder High Velocity Oxyfuel Spraying

In the early 1980's Browning and Witfield, using rocket engine technologies, introduced a unique method of spraying metal powders. The technique was referred to as High Velocity Oxy-Fuel (HVOF). The process utilizes a combination of oxygen with various fuel gases including hydrogen, propane, propylene, hydrogen and even kerosene. In the combustion chamber, burning by-products are expanded and expelled outward through an orifice where at very high velocities.

Powders to be sprayed via HVOF are injected axially into the expanding hot gases where they are propelled forward, heated and accelerated onto a surface to form a coating. Gas velocities exceeding Mach 1 have been reported with temperatures approaching 2,300°C (4,172°F). The coupling of inertially driven/highly plasticized particles can achieve coatings approaching that of theoretical density. Disadvantages include low deposition rates and in-flight the oxidation of particles. Future efforts will focus on applying thick coatings and improvements in processes control including in-flight transit time and exposure to atmospheric oxygen.

If you have any interest in our products, please feel free to contact us by email: sales@chinatungsten.com or by telephone: +86 592 5129696.

More info>>