3D Printing Performance Requirements on Metal Powder

The performance requirements of 3D printing on metal powder mainly include purity, particle size distribution, powder morphology, powder fluidity and bulk density.

1.Purity

Ceramic inclusions will significantly reduce the performance of the final part, and these inclusions generally have a high melting point and are difficult to be sintered. Therefore, there must be no ceramic inclusions in the powder.

In addition, the content of oxygen and nitrogen also needs to be strictly controlled. At present, the powder preparation technology used for metal 3D printing is mainly atomization method. The powder has a large specific surface area and is easy to be oxidized. In aerospace and other special applications, customers have more strict requirements on this indicator, such as the oxygen content of high-temperature alloy powder is 0.006% - 0.018%, that of titanium alloy powder is 0.007% - 0.013%, and that of stainless steel powder is 0.010% - 0.025%.

2.Powder Particle Size Distribution

Different 3D printing equipment and forming process have different requirements on powder particle size distribution. At present, the commonly used particle size range of metal 3D printing is 15-53 μ M (fine powder), 53-105 μ M (coarse powder), which can be extended to 105-150 in some cases μ M (coarse powder).

The selection of particle size of metal powder for 3D printing is mainly based on the metal printers with different energy sources. The printers with laser as the energy source are suitable for 15-53 because of their fine focusing spot and easy melting of fine powder μ M powder is used as consumables, and the powder supply method is powder layer by layer; Powder laying printer with electron beam as energy source, with slightly thick focus spot, is more suitable for melting coarse powder, and is suitable for 53-105 μ M coarse powder; For coaxial powder feeding printer, particle size of 105-150 can be used μ M powder as consumables.

3. Powder Morphology

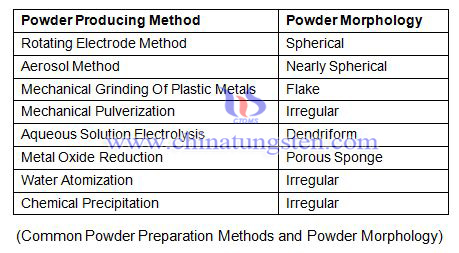

Powder morphology is closely related to the preparation method of powder. Generally, when the metal gas or molten liquid is transformed into powder, the shape of powder particles tends to be spherical. When the solid state is transformed into powder, the powder particles are mostly irregular, while the powder prepared by aqueous solution electrolysis is mostly dendritic.

In general, the higher the sphericity, the better the fluidity of the powder particles. The sphericity of 3D printing metal powder is required to be above 98%, which makes it easier to spread and feed powder during printing.

The above table shows the metal powder morphology corresponding to different powder preparation methods. It can be seen that, except for the gas atomization method and the rotating electrode method, the powder morphology prepared by other methods is non spherical. Therefore, the gas atomization method and the rotating electrode method are the main preparation methods of high-quality 3D printing metal powder.

4. Powder Fluidity and Bulk Density

Powder fluidity directly affects the uniformity of powder spreading and the stability of powder feeding in the printing process.

The fluidity is related to the powder morphology, particle size distribution and bulk density. The larger the powder particles are, the more regular the particle shape is, and the smaller the proportion of ultra-fine powder in the particle size composition is, the better the fluidity is; When the particle density is constant, the relative density increases, and the powder fluidity increases. In addition, the adsorption of water and gas on the particle surface will reduce the fluidity of the powder.

Loose packing density refers to the mass of powder per unit volume when the powder sample naturally fills the specified container. Generally, the coarser the powder particle size is, the greater the loose packing density is. The powder with coarse and fine matching can obtain a higher loose packing density. The effect of loose packing density on the density of the final metal printing product is uncertain, but the increase of loose packing density can improve the fluidity of the powder.

If you have any interest in spherical tungsten powder, please feel free to contact us by email: sales@chinatungsten.com or by telephone: +86 592 5129696.

More info>>