Plasma is an ionized gaseous cloud composed of free electrons, positive ions, neutral atoms and molecules. Because of its unique properties some have referred to it as the "fourth state of matter". Plasma is generated whenever sufficient energy is imparted to a gas to cause some of it to ionize.

If a gas is heated above 5,000°C (9,032°F) chemical bonds are broken down and its atoms undergo violent random movements. This results in atomic collisions that cause some electrons to become detached from their nuclei. Electrons are the negatively charged constituents of atoms; so having lost an electron the heavier nuclei, with any remaining electrons, become positively charged. When a gas undergoes this disruption it is said to be ionized and the cloud it has become is identified as plasma. Its behavior involves complex interactions between electromagnetic and mechanical forces. Plasma is present in any e

lectrical discharge even one as in an ordinary arc or in a vacuum tube. It is cold plasma that excites the phosphors within a fluorescent tube.

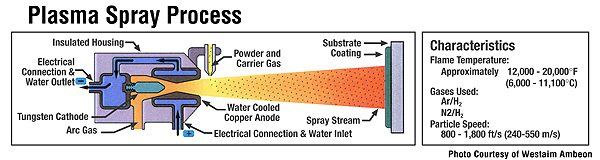

Plasma has been known for a considerable time. In commercial technology they are considered as hot streams of particles attaining temperatures greater than 10,000°C (18,032°F). Today's plasma spray guns are sufficiently robust to produce temperatures from 5,000°C (9,032°F) to 16,000°C (28,832°F) for long periods. These guns are referred to as "nontransferred arc plasma generators". The generator is essentially an electric arc working in a constricted space. Two electrodes, front (anode) and rear (cathode), are contained in a chamber, as is the arc through which the effluent (the operating gas) passes, a concept developed by H. Gerdien (2) of Germany in the1920s. However, at that time, it was afforded little interest, as there was no apparent need for such high temperatures. The advent of the space age changed this and workable systems were commercially introduced in the 1950s.

Plasma generators work on the concept that if sufficient voltage is applied to two electrodes, separated by a small gap, the difference in potential at that moment causes electrons to be extracted from the cathode. The electrons accelerate and speed toward the anode. If a gas is inserted in the gap between the two electrodes, its atoms will collide with the ensuing electrons and themselves, causing more electrons to detach and travel towards the anode. Meanwhile, the nuclei stripped of their electrons, and positively charged, move to the cathode. Thereby, the gas in the gap has been ionized, becoming electrically conductive - a plasma arc; it exits through an orifice in the anode as a plasma stream, containing only electrons and ionized gas is formed (7). Meanwhile the issuing plasma stream, reaching temperatures exceeding 9,000°C (16,232°F), begins to cool and the once ionized gas begins to recombine.

Most commercial plasma guns are fundamentally simple in design, consisting of a chamber and front nozzle (anode) in which there is an orifice. The chamber and nozzle are water-cooled. At the rear of the chamber is nother electrode, also water-cooled. This rear electrode is non-consumable and is fashioned from thoriated tungsten (see graphic above). A port, somewhere within the chamber, allows the high-pressure plasma forming gas, or gases, to enter. A high-frequency spark initiates operation and is discontinued upon ignition. It should be noted that the high-pressure gas cools the outer layer of the plasma arc so extreme heat is kept away from the nozzle bore.

Typical plasma forming gases include argon, nitrogen, hydrogen and helium. They may be used either alone or in combination: viz, argon-hydrogen, argon-helium, nitrogen-hydrogen, etc. Argon and nitrogen are generally utilized as primary plasma gases and hydrogen is favored as a secondary as it aids in producing a "hotter" plasma. Nitrogen is less expensive than argon so, based on economics, is more widely used than argon. Helium tends to expand the plasma and when used in combination with argon produces a "high velocity plasma" that exits the nozzle at about 488 m/sec (1,600 ft/sec). Argon/hydrogen and nitrogen/hydrogen exit velocities have been measured at roughly 366 m/sec (1,200 ft/sec). As most plasma guns are designed to spray powders, the powder is introduced through an external port at the nozzle orifice. Hardware is also available for injecting powder internally upstream into the nozzle bore. The primaryplasma forming gas is usually used as a carrier to transport the powder to the plasma stream.

If you have any interest in our products, please feel free to contact us by email: sales@chinatungsten.com or by telephone: +86 592 5129696.

More info>>

1.Tungsten Powder

2.Catalog of Tungsten Powder

3.E-catalog of Tungsten Powder

|